#prusawire #3dprinting

*Ask in the Positron3D Discord in #prusawire-discussions for help with your build!*

## Resources

- [Voron Software Installation Guide](https://docs.vorondesign.com/build/software/) for some good resources on Mainsail (Klipper on Raspberry Pi) and Control Board firmware.

- [Raspberry Pi OS based \| MainsailOS](https://docs-os.mainsail.xyz/getting-started/raspberry-pi-os-based)

- [Welcome to Mainsail \| Mainsail](https://docs.mainsail.xyz/)

- [GitHub - bigtreetech/BIGTREETECH-SKR-mini-E3](https://github.com/bigtreetech/BIGTREETECH-SKR-mini-E3)

- [BIGTREETECH-SKR-mini-E3/firmware/V3.0/Klipper at master · bigtreetech/BIGTREETECH-SKR-mini-E3 · GitHub](https://github.com/bigtreetech/BIGTREETECH-SKR-mini-E3/tree/master/firmware/V3.0/Klipper)

## Configuration

Start with the [Positron3D Prusawire Configuration](https://github.com/Positron3D/prusawire-klipper-config) settings and profiles.

More detail general instructions are found at [Software Configuration \| Voron Documentation](https://docs.vorondesign.com/build/software/configuration.html).

### Sensorless Homing

If you are running the Einsy board, congrats, you are now done.

For the BTT SKR Mini E3, some further tuning likely needs to happen. Refer to [this guide](https://gist.github.com/clee/9108f7717defce8b1222698f816def0a#finding-the-right-stallguard-threshold) by clee on setting the correct stallguard threshold.

### Input Shaper

Some defaults have been provided, but they are no doubt unsuitable for your exact machine. We recommend installing [ShakeTune](https://github.com/Frix-x/klippain-shaketune) for measuring resonances, and reading the [Klipper guide](https://www.klipper3d.org/Measuring_Resonances.html#max-smoothing) on understanding which value to choose.

**Y Axis Input Shaping**: This requires an external accelerometer (eg LDO Input Shaper) to be mounted to your heated bed.

## Build Log - "THOTH STATION"

*This is a running log of what I've done for my Prusawire PW.0011. It may or may not all apply to your build / setup.*

- Mainsail

- Grab latest Raspberry Pi imager from: [Raspberry Pi software – Raspberry Pi](https://www.raspberrypi.com/software/)

- Run pi-imager

- 128GB Samsung Pro Endurance microSD Card

- Pi 4

- Mainsail OS

- Settings

- Hostname: {HOSTNAME_HERE}

- Username: {USERNAME}

- Password: {1PASSWORD}

- WiFi: {WIFI_SSID} / password

- WLAN Country = US

- Time Zone: America/New_York

- Enable SSH

- Write image to microSD card

- Inserted microSD card into Raspberry Pi.

- Turned on printer.

- Klipper on SKR Mini E3 V3

- Insert MicroCenter 16GB microSD Card into Mac.

- Format as FAT32

- `ssh {USERNAME}@{HOSTNAME_HERE}`

- Make the Klipper firmware for the control board:

- `cd ~/klipper/`

- `make menuconfig`

- Select "Enable extra low-level configuration options"

- Microcontroller: "STMicroelectronics STM32"

- Processor Model: "STM32G0B1"

- Bootloader offset: "8KiB bootloader (stm32duino)"

- Clock reference: "8MHz Crystal"

- Communication interface: "USB on PA11/PA12"

- Press Q and then Y to save.

- `make`

- Copy the `klipper.bin` from the output directory to your local machine:

- ex: `scp {USERNAME}@{HOSTNAME}:~/klipper/out/klipper.bin ~/`

- Copy the `klipper.bin` to the root of the SD card as `firmware.bin`

- Power off SKR-Mini-E3-V3.0

- Insert microSD Card

- Power on SKR-Mini-E3-V3.0

- Confirm flash was successful by running `ls /dev/serial/by-id` on the Raspberry Pi.[](https://github.com/bigtreetech/BIGTREETECH-SKR-mini-E3/blob/master/firmware/V3.0/Klipper/Images/stm32g0b1_id.png)

- Follow instructions at: [GitHub - Positron3D/prusawire-klipper-config: Prusawire configuration for Klipper](https://github.com/Positron3D/prusawire-klipper-config)

- `cd ~/`

- `git clone https://github.com/Positron3D/prusawire-klipper-config.git ~/printer_data/config/prusawire`

- `cd ~/printer_data/config/`

- Edit `moonraker.conf`:

- Add the following to the end of it:

```

[update_manager prusawire-config]

type: git_repo

primary_branch: main

path: ~/printer_data/config/prusawire

origin: https://github.com/Positron3D/prusawire-klipper-config.git

managed_services: klipper

```

- `cd ~/printer_data/config/prusawire/`

- `cp printer.cfg.example ../printer.cfg`

- `cd ~/printer_data/config/`

- Edit `printer.cfg`:

- Uncomment the correct section for the control board you're using.

- BTT SKR Mini E3 in my case.

- Edit the serial line to use the output from `ls /dev/serial/by-id`

- Uncomment the correct section for the toolhead board you're using.

- LDO Nitehawk SB in my case.

- Edit the serial line to use the output from `ls /deve/serial/by-id`

- Uncomment the correct section for the probe you're using.

- SuperPINDA on Nitehawk SB in my case.

- Uncomment the correct section for the filament sensor you're using.

- LDO Nitehawk SB in my case.

- Under LCD Screens, uncomment the info for the MK3 LCD if using, or add info for BTT HDMI 5:

- For BTT HDMI 5, this section isn't need. The installation of KlipperScreen below is all you need.

- Edit `sensor_type` to be your sensor

- Prusawire Config includes what is probably the correct sensor type for you using Revo.

- For Bambu X1C Hot End in SB:

- `sensor_type: ATC Semitec 104GT-2`

- `max_power_ 0.8`

- Access the Mainsail instance: http://{HOSTNAME_HERE}

- At this point, we should see all the printer controls! Else, fix any errors.

- Klipper Control Panel on the BTT HDMI 5 Display with KlipperScreen

```bash

git clone https://github.com/jordanruthe/KlipperScreen.git

./KlipperScreen/scripts/KlipperScreen-install.sh

```

- Default settings should be fine.

- Sensorless Homing with BTT SKR Mini E3 V3.0

- ** *For the BTT SKR Mini E3, some further tuning likely needs to happen. Refer to [this guide](https://gist.github.com/clee/9108f7717defce8b1222698f816def0a#finding-the-right-stallguard-threshold) by clee on setting the correct stallguard threshold.*

- **NOTE: For the BKK SKR Mini E3 V3.0 --> must put jumpers on X-STOP and Y-STOP to allow sensorless homing!**

- NOT Z-STOP if you are using the SuperPINDA!

- TMC2209 is used on the SKR Mini E3

- PID Tuning for Hot End:

- In Mainsail, enter the following commands to set the PID Tuning for the Hot End:

- `PID_CALIBRATE heater=extruder TARGET=250`

- `SAVE_CONFIG`

- Results 2025-09-25 @ 1645: `PID parameters: pid_Kp=38.373 pid_Ki=12.182 pid_Kd=30.219`

- PID Tuning for Heat Bed

- In Mainsail, enter the following commands to set the PID Tuning for the Heat Bed:

- `PID_CALIBRATE heater=heater_bed TARGET=65`

- `SAVE_CONFIG`

- Results 2025-09-29 @ 1400: `PID parameters: pid_Kp=49.793 pid_Ki=0.712 pid_Kd=870.137`

- ==TODO: FILAMENT RUNOUT SENSOR==

- See [[Prusawire Software Installation and Configuration#Filament Runout Sensor]] for hardware setup.

- Configuration Info for filament runout sensor if using.

- NEOPIXEL Stealthburner Configuration for Rainbow Barf LED

- See below [[Prusawire Software Installation and Configuration#Rainbow Barf LED Hardness - Neopixel]]

- ==**TODO: Input Shaper:**== *Some defaults have been provided, but they are no doubt unsuitable for your exact machine. We recommend installing [ShakeTune](https://github.com/Frix-x/klippain-shaketune) for measuring resonances, and reading the [Klipper guide](https://www.klipper3d.org/Measuring_Resonances.html#max-smoothing) on understanding which value to choose.*

- ==**TODO: Y-Axis Input Shaping:**== *This requires an external accelerometer (eg LDO Input Shaper) to be mounted to your heated bed.*

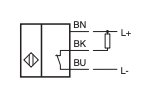

### BTT SKR Mini E3 V3.0 Control Board

![[Pasted image 20250925155457.png]]

## SuperPINDA Probe

Brown = +5V

Blue = GND

Black = Signal

### NiteHawb-SB

Make sure there isn't a "!" in the superpinda config or it won't work.

```

[probe]

pin: ^nitehawk:gpio13

```

On NiteHawk-SB, use the XY Endstop Port. Connect Black(Signal) to GPIO13.

![[Pasted image 20250926161441.png|500]]

### SB2209 USB

[EBB SB2209 USB V1.0 - BIGTREETECH WIKI](https://bttwiki.com/EBB%20SB2209%20USB.html)

Use the PROBE port (5-pin)

![[Pasted image 20250928133755.png|500]]

### SB2209 CAN

Use the sample SB2209 USB config provided and change the pin to be a CANbus pin:

This will vary based on what your probe input pin is...

`pin: EBBCan: PB5`

![[Pasted image 20250928140517.png]]

![[Pasted image 20250928134924.png|300]]

![[Pasted image 20250928134902.png|500]]

### Rainbow Barf LED Hardness - Neopixel

SB Rainbow Barf Config to include at the end of the toolboard config (`ldo_nighthawk_sb.cfg` in my case)

[whopping\_Voron\_mods/LEDs/Rainbow\_Barf\_Logo\_LED/Code/stealthburner\_led\_effects\_barf.cfg at main · tanaes/whopping\_Voron\_mods · GitHub](https://github.com/tanaes/whopping_Voron_mods/blob/main/LEDs/Rainbow_Barf_Logo_LED/Code/stealthburner_led_effects_barf.cfg)

**Install the Klipper-LED-Effects Plugin**

[BARF-Led-Kit/stealthburner\_leds.cfg at main · 3DPTronics/BARF-Led-Kit · GitHub](https://github.com/3DPTronics/BARF-Led-Kit/blob/main/stealthburner_leds.cfg) + [GitHub - julianschill/klipper-led\_effect: LED effects plugin for klipper](https://github.com/julianschill/klipper-led_effect)

```bash

cd ~

git clone https://github.com/julianschill/klipper-led_effect.git

cd klipper-led_effect

./install-led_effect.sh

```

### Filament Runout Sensor

- Omron D2F-5L Switch

- [Digikey Omron D2F-5L Switch](https://www.digikey.com/en/products/detail/omron-electronics-inc-emc-div/D2F-5L/8593137)

- 5.5mm Stainless Steel Ball Bearing

- [Amazon.com: uxcell 50pcs 5.5mm 304 Stainless Steel Bearing Balls G100 Precision : Industrial & Scientific](https://www.amazon.com/dp/B09DSH1GL6?ref=ppx_yo2ov_dt_b_fed_asin_title)

If using NiteHawk-SB, can combine with the SuperPINDA JST connector to grab 5VDC, GND, and the otherwise unused GPIO12 pin.

### ShakeTune - Input Shaping

Usage Documentation: [klippain-shaketune/docs/README.md at main · Frix-x/klippain-shaketune · GitHub](https://github.com/Frix-x/klippain-shaketune/blob/main/docs/README.md)

1. Be sure to have a working accelerometer on your machine and a `[resonance_tester]` section defined. You can follow the official [Measuring Resonances Klipper documentation](https://www.klipper3d.org/Measuring_Resonances.html) to configure it.

2. Install Shake&Tune by running over SSH on your printer:

```shell

wget -O - https://raw.githubusercontent.com/Frix-x/klippain-shaketune/main/install.sh | bash

```

3. Then, append the following to your `printer.cfg` file and restart Klipper:

```

[shaketune]

# result_folder: ~/printer_data/config/ShakeTune_results

# Path where the processed results will be stored. If the folder doesn't exist,

# it will be automatically created. You can change this if you'd like to store

# results in a different location.

# number_of_results_to_keep: 10

# This setting defines how many results you want to keep in the result folder.

# Once the specified number is exceeded, older results will be automatically deleted

# to free up space on the SD card and avoid cluttering the results folder.

# keep_raw_data: False

# If set to True, Shake&Tune will store both the processed graphs and the raw accelerometer

# .stdata files in the results folder. This can be useful for debugging or archiving purposes.

# Please always attach them when reporting any issues on GitHub or Discord.

# show_macros_in_webui: True

# Mainsail and Fluidd doesn't create buttons for system commands (macros that are not part

# of the printer.cfg file). This option allow Shake&Tune to inject them into the webui at runtime.

# If set to False, the macros will be hidden but still accessible from the console by typing

# their names manually, which can be useful if you prefer to encapsulate them into your own macros.

# timeout: 600

# This defines the maximum processing time (in seconds) to allows to Shake&Tune for generating

# graphs from a .stdata file. 10 minutes should be more than enough in most cases, but if you have

# slower hardware (e.g., older SD cards or low-performance devices), increase it to prevent timeouts.

# measurements_chunk_size: 2

# Each Shake&Tune command uses the accelerometer to take multiple measurements. By default,

# Shake&Tune will write a chunk of data to disk every two measurements, and at the end of the

# command will merge these chunks into the final .stdata file for processing. "2" is a very

# conservative setting to avoid Klipper Timer Too Close errors on lower end devices with little

# RAM, and should work for everyone. However, if you are using a powerful computer, you may

# wish to increase this value to keep more measurements in memory (e.g., 15-20) before writing

# the chunk and avoid stressing the filesystem too much.

# max_freq: 200

# This setting defines the maximum frequency at which the calculation of the power spectral density

# is cutoff. The default value should be fine for most machines and accelerometer combinations and

# avoid touching it unless you know what you're doing.

# dpi: 300

# Controls the resolution of the generated graphs. The default value of 300 dpi was optimized

# and strikes a balance between performance and readability, ensuring that graphs are clear

# without using too much RAM to generate them. Usually, you shouldn't need to change this value.

```